Introduction

The idea of making an artificial stone dates back thousands of years ago. The Romans used to mix lime, pozzolan, water and aggregates (sand, gravel, etc.) to obtain a material that could be poured like a liquid and, once hardened, behaved like a stone.

The dome of Pantheon was built in this way and is still considered an incredible feat of engineering, standing for twenty centuries.

In the Nineteenth Century, the invention of Portland cement revolutionized the technology of construction materials and transformed the receipt of the ancient Romans into modern concrete.

In this period Europe saw its first buildings constructed with steel-reinforced concrete, a groundbreaking innovation for architecture and engineering applications.

Concrete is one of the most used construction materials in the World.

Three Pillars

- Fresh-state workability

The ability of concrete to be cast in place without voids of defects

- Compressive strength

The ability of hardened concrete to resist to loads in the building or structure

- Durability

The ability of hardened concrete to resist to environmental aggression

The fulfillment of these requirements depends on how concrete is formulated and manufactured. This is the reason why the knowledge of concrete characteristics and behavior is of great practical interest

Composition

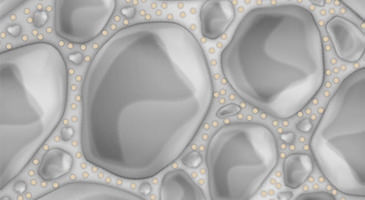

Aggregates are sand and gravel. They are the “skeleton” of concrete and:

- they provide strength and stiffness

- they counteract the shrinkage of cement during hardening, avoiding cracking

- they reduce the overall cost of concrete

Cement Paste is formed by the mixing of cement, water and possibly chemical admixtures. Cement paste has the role of binding the aggregates, but has also a primary influence on

- workability, strength, durability of final concrete.

Concrete can be seen as a composite material: a dispersed phase (aggregates) bound by a matrix (the cement paste). The roles of aggregates and cement paste within concrete are different.